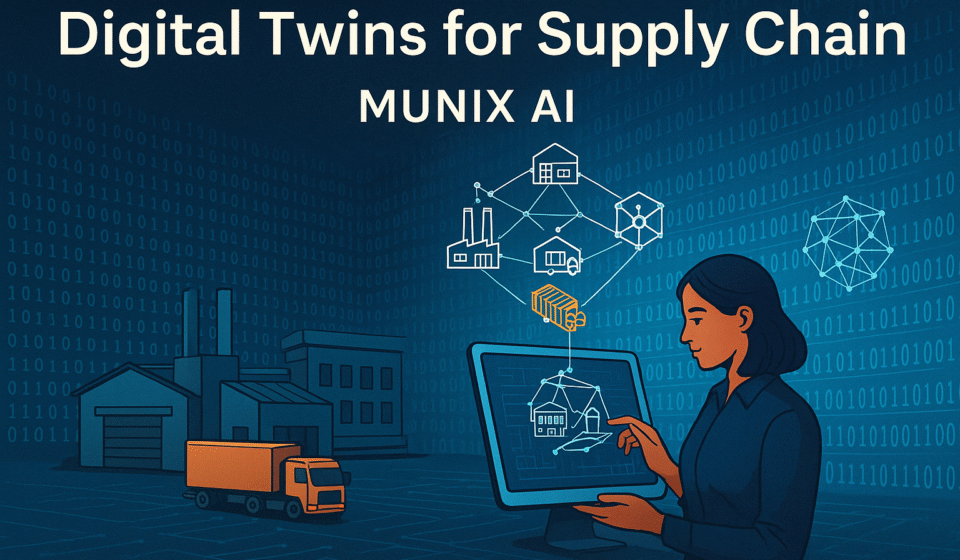

Digital Twins for Supply Chain: What They Are and Why They Matter

Seeing Your Supply Chain — Clearly, Completely, and In Real Time

The modern supply chain is a living organism. It stretches across continents, involves hundreds of suppliers, thousands of shipments, and millions of moving parts. Yet, despite this complexity, many organizations still rely on outdated tools — static spreadsheets, siloed systems, and rear-view reporting.

Table Of Content

- Seeing Your Supply Chain — Clearly, Completely, and In Real Time

- What Exactly Is a Digital Twin?

- Why Digital Twins Are a Game-Changer for Supply Chain Leaders

- ✅ 1. End-to-End Visibility — Real-Time, Not After-the-Fact

- 🚩 2. Proactive Risk Management

- 🚛 3. Smarter, Data-Driven Decisions

- 🌿 4. Align with ESG and Sustainability Goals

- Digital Twins at Work: Real-World Use Cases

- The Mindset Shift: From Control to Confidence

- How to Get Started: The Digital Twin Roadmap

- Conclusion: Why Digital Twins Are the Future of Supply Chain Resilience

- Ready to Future-Proof Your Supply Chain?

In an era of global disruptions, shifting demand patterns, and growing sustainability pressures, this reactive approach is no longer enough.

What if you could create a living, breathing replica of your entire supply chain — one that mirrors reality, updates in real time, and allows you to simulate the future before it happens?

This is the promise of the Digital Twin.

What Exactly Is a Digital Twin?

A digital twin is not just a digital model. It’s a dynamic, data-driven mirror of your physical supply chain network — capturing every supplier, production site, warehouse, transport lane, and inventory node in real time.

But more importantly, a digital twin isn’t just about visualizing your supply chain. It’s about understanding it. It’s about anticipating problems before they occur, testing decisions before they’re made, and aligning plans with actual performance.

Why Digital Twins Are a Game-Changer for Supply Chain Leaders

✅ 1. End-to-End Visibility — Real-Time, Not After-the-Fact

Stop relying on fragmented reports and lagging indicators. A digital twin provides a single source of truth across your entire network — from supplier performance to inventory positions to in-transit shipments.

🚩 2. Proactive Risk Management

What happens if a supplier goes offline? How will a port delay ripple through your network? With a digital twin, you can run what-if scenarios and stress tests — before issues escalate into costly disruptions.

🚛 3. Smarter, Data-Driven Decisions

Should you shift inventory closer to demand centers? Which shipping routes minimize both cost and emissions? Digital twins enable scenario planning and optimization, empowering leaders to act with confidence, not guesswork.

🌿 4. Align with ESG and Sustainability Goals

Model your carbon footprint. Optimize resource utilization. Prove your sustainability commitments with hard data — not estimates. Digital twins help organizations make responsible, measurable progress toward ESG targets.

Digital Twins at Work: Real-World Use Cases

| Use Case | How Digital Twins Add Value |

|---|---|

| Demand Planning | Anticipate shifts in customer demand and adapt plans dynamically. |

| Inventory Optimization | Balance stock levels across the network without overstocking or risking stockouts. |

| Supplier Risk Monitoring | Detect early warning signs of supplier disruptions and identify alternative options. |

| Logistics and Transport | Predict ETAs, reroute shipments, reduce freight costs, and improve service reliability. |

| Disruption Recovery | Model responses to natural disasters, geopolitical events, or market shocks. |

The Mindset Shift: From Control to Confidence

The value of a digital twin goes beyond technology. It represents a leadership mindset shift:

| Reactive Supply Chain | Predictive, Twin-Enabled Supply Chain |

|---|---|

| Operates on past data | Plans with real-time insights and foresight |

| Manual decision-making | Automated, scenario-based recommendations |

| Disruption-driven responses | Proactive risk mitigation and resilience building |

| Siloed functions | Integrated, collaborative decision-making |

How to Get Started: The Digital Twin Roadmap

- Map Your Network: Visualize your supply chain nodes — suppliers, warehouses, factories, customers.

- Connect Your Data: Integrate ERP, IoT, logistics systems, and external feeds like weather or market data.

- Identify High-Impact Use Cases: Focus on pain points where better visibility, prediction, or optimization could move the needle.

- Pilot and Prove Value: Start small. Demonstrate ROI. Scale across the enterprise.

- Enable Prescriptive Actions: Close the loop by linking your twin insights directly to planning and execution systems.

Conclusion: Why Digital Twins Are the Future of Supply Chain Resilience

In today’s unpredictable world, leaders need more than reports — they need foresight. They need a system that doesn’t just describe the past but predicts the future and prescribes the next best action.

Digital twins provide that edge.

They turn complexity into clarity.

Uncertainty into control.

And data into decisions that drive performance.

The question isn’t whether your supply chain will face disruptions — it’s whether you’ll be ready.

Ready to Future-Proof Your Supply Chain?

Discover how digital twin technology can unlock resilience, agility, and smarter decision-making for your business.

Contact our team to explore your next step.